Metal Injection Molding Materials

Request a Quote

- Steel (4600, case carburized)

- Stainless Steel (17-4PH, 316L, Duplex, 430L, 440C)

- Soft Magnetic (Fe-3Si, 50Ni-50Fe, 430L)

- Controlled Expansion (Invar, Kovar, Alloy 36)

- Tool Steel (M2, T15, D2)

- Nickel

MIM Materials Overview

MIM 2200 Steel

MIM 2200 Steel

Applications in Automotive Systems:

- Lock Plate for Headrest Adjuster in Seating System

- Stop Cam in Sun Roof System

- Sidebar in ignition lock

- Actuator in steering column

MIM Duplex Stainless Steel

MIM Duplex Stainless Steel

Applications in High Security Locks:

- 3-Pin, 4-Pin, and 5-Pin Sidebars

- Retainer Plug

- Cylinder Case

- MIM 17-4PH Stainless Steel

- Ordnance Application – Stabilizer Fin

- Lock Application – Cylinder Bolt

- MIM 440C Stainless Steel

- Fine, well-distributed carbides in a martensitic matrix provides high strength and hardness with excellent wear resistance

- Processed to full density to compete directly with wrought and cast material

- MIM F15 (trade name “Kovar”)

- MIM Alloy 36 (trade name “Invar”)

- MIM Alloy 42

- Commonly used for glass-to-metal seals

MIM Controlled Thermal Expansion Alloys

MIM Stainless Steel

| GRADE | TYPE | DESCRIPTION | APPLICATIONS |

|---|---|---|---|

| MIM 430L | Ferritic | Magnetic stainless steel with resistance to atmospheric corrosion and general oxidation. Lower cost than nickel-containing austenitic stainless steels. | Sensors, armatures, and pole pieces that require some resistance to corrosion |

| MIM 316L | Austenitic | Non-magnetic stainless steel with excellent corrosion resistance, toughness, and ductility | Medical and dental devices, marine components, and non-magnetic housings |

| MIM Duplex | Duplex (Ferritic/Austenitic) |

Weakly magnetic stainless steel providing a mix of properties between the austenitic and ferritic grades | Lock components |

| 17-4PH | Precipitation Hardening | Provides an excellent combination of strength, hardness, and corrosion resistance | Ordnance components, high strength fasteners, fiber optic connectors, and medical devices |

| MIM 440C | Martensitic | Provides high strength, hardness, and resistance to wear with moderate resistance to corrosion | Wear plates, fuel injection nozzles, and cutting instruments. |

MIM Low Alloy Steel

| GRADE | TYPE | DESCRIPTION | APPLICATIONS |

|---|---|---|---|

| MIM 2200 | Low Carbon Nickel-Steel | Provides outstanding toughness and ductility; carburized surface provides an excellent wear surface with a tough core | Lubricated safety and security devices, automotive interior components, and coated or plated hardware |

Soft Magnetic Alloys

| GRADE | TYPE | DESCRIPTION | APPLICATIONS |

|---|---|---|---|

| MIM Fe | Iron | Provides high magnetic induction for DC applications where low coercive force and high permeability are not required | Pole pieces, sensor probes, and solenoid end caps |

| MIM 3Si | Silicon-Iron | Provides higher permeability and lower coercive force compared to iron | Solenoid switches, armatures, pole pieces, and relays |

| MIM 50Ni | Nickel-Iron | Provides higher permeability and reduced coercive force compared to 3Si, at the expense of magnetic induction | Pole pieces, cores, and relays |

| MIM 430L | Ferritic | Combines good magnetic output with corrosion resistance | Magnetic probes, sensors, armatures, and pole pieces |

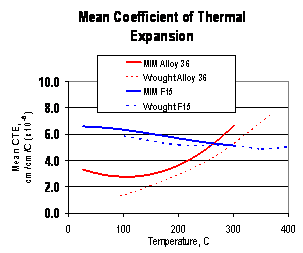

Low Expansion Alloys

| GRADE | TYPE | DESCRIPTION | APPLICATIONS |

|---|---|---|---|

| MIM F15 |

Fe-28Ni-18Co | F15 (trade name Kovar) provides a low and consistent coefficient of linear expansion up to 750 °F (400 °C) | Commonly used when glass-to-metal seals are required |

| MIM Alloy 36 | Fe-36Ni | Alloy 36 (trade name Invar) provides a very low coefficient of linear expansion up to 300 °F (150 °C) | Commonly used when glass-to-metal seals are required |

| MIM Alloy 42 | Fe-42Ni | Alloy 42 provides a low and consistent coefficient of linear expansion up to 575 F (300 °C) | Commonly used when glass-to-metal seals are required |

Custom Blends

Jiangsu Tech realizes that our customers' needs are as various as the alloys the PM process can provide. Our R&D center and engineering staff enjoys assisting customers who require special materials for specific applications.